Add to Cart

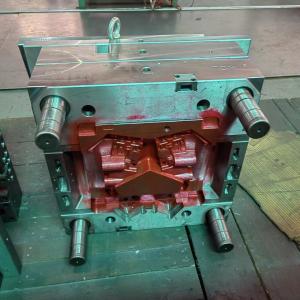

Plastic Injection Tooling is an essential part of the plastic injection molding process. It is used to create precision plastic components and parts with high accuracy and repeatability. The tooling is mainly composed of the mold base, mold components, and other parts. The mold base can be LKM, HASCO, or DME, and the mold components can be Yudo, Mold Master, Husky, etc. With these parts, the plastic injection tooling can provide high precision and accuracy with a tolerance of ±0.01mm. The tooling has a long mold life of 500,000-1,000,000 shots, depending on the complexity of the product. Plastic Injection Tooling is widely used in many industries, such as automotive, electronics, medical, and more. It is the perfect choice for plastic injection molding projects.

| Parameter | Value |

|---|---|

| Mold Life | 500,000-1,000,000 Shots |

| Cavity Number | Single Or Multi-Cavity |

| Mold Components | Yudo, Mold Master, Husky, Etc. |

| Surface Finish | Customized |

| Lead Time | Depends On The Complexity Of The Product |

| Tolerance | ±0.01mm |

| Color | Customized |

| Process | Injection Tooling |

| Runner System | Hot Or Cold |

| Mold Base | LKM, HASCO, DME |

Plastic injection tooling is a versatile and cost-effective way to produce plastic parts and components. Howe's HW-885 model is renowned for its high-quality and long-lasting performance, certified by ISO standards. With a minimum order quantity of 1 set and custom surface finish, the mold life of this tooling can range from 500,000 to 1,000,000 shots, making it ideal for multiple applications. The cavities can be single or multi-cavity, and the mold base is available in LKM, HASCO, or DME. The design software used is UG, Pro/E, Solidworks, or Auto CAD.

This plastic injection tooling can be used in a variety of industries, such as automotive, medical, or consumer products. It is suitable for products that require precision, such as connectors, clamps, valves, and electronic components. Its high accuracy and repeatability make it an ideal choice for complex 3D parts. Furthermore, it can be used for small and large-scale production runs, making it a very cost-effective solution for businesses.

The price of this tooling is negotiable and the delivery time is 25 to 40 days. The supply ability is 60 sets per month. The packaging is customized as per the customer's requirement, usually wooden cases for moulds and cartons for parts. Payment terms are T/T.

For reliable and high-quality plastic injection tooling, Howe's HW-885 model is the ideal choice.

Are you looking for reliable and high-quality Molding Injection Tooling? Look no further than Howe's Plastic Injection Tooling with model number HW-885. This product is made of quality plastic, and the size and color can be customized, making it perfect for your unique needs. All tooling for plastic injection is certified by ISO and the minimum order quantity is 1 set. It is available in single or multi-cavity and the mold base is compatible with LKM, HASCO, and DME. The price is negotiable, and the delivery time is 25-40 days. Payment terms are T/T, and the supply ability is 60 set/month. Packaging is available in wooden cases for moulds, cartons for parts, or as your requirement.

We offer technical support and service for our Plastic Injection Tooling product. Our experienced engineers provide comprehensive technical service, from initial design consultation, to mold design and manufacture, to final product delivery.

Our technical support includes:

We provide comprehensive technical support and service for Plastic Injection Tooling, so you can rest assured that you will have the support you need. Contact us today for more information.

Plastic injection tooling is safely packaged and shipped with the following methods: